Dry etching

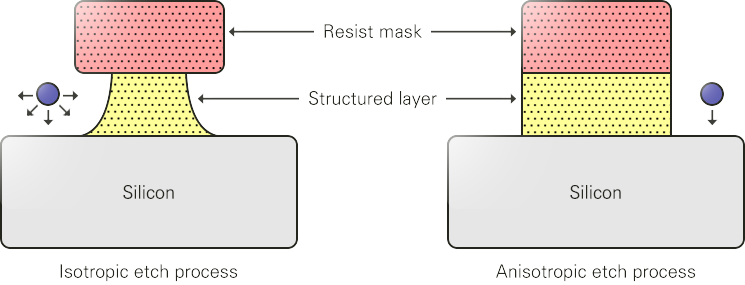

- Isotropic Etching

- Film etching only through a chemical reaction between film surface and radical

- Anisotropic etching through random mobility of radical

- High selectivity (chemical reaction)

- Low damage to the bottom layer

- Generation of undercut and difficulty with fine patterns

- Excessive use of chemicals leading to environmental problems

- Anisotropic etching

- Etching by a chemical reaction stimulated by ions accelerated by self-bias

- Almost no side erosion because of ions accelerated in one direction

- Superior etching resolution (1um or below)

- Damage to the bottom layer possible due to etching by physical impact

Dry etching Types

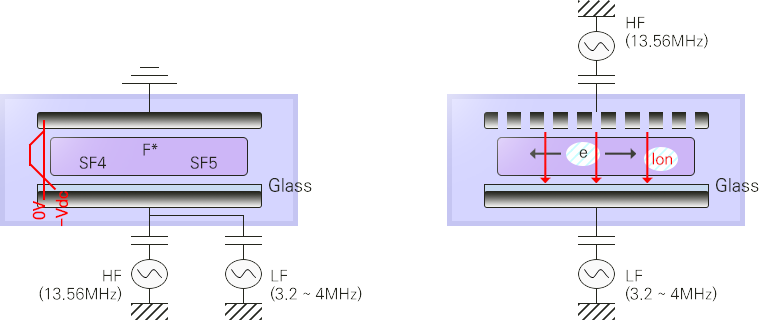

- ECCP

(Enhanced Capacitive Coupled Plasma) -

CCP (Capacitive Coupled Plasma) is a device for generating

plasma with the structure in which a dielectric is inserted

between parallel plates -

The plasma density is lower than the method of ICP

but can create uniform plasma in a relatively simple manner -

It is widely used for semiconductor device and thin film Si

solar cell manufacturing processes because large-surface

etching and deposition is possible

- ICP

(Inductive Coupled Plasma) -

The method of ICP (Inductive Coupled Plasma) allows

electricity to flow through a coil-shaped antenna located

outside a reactive chamber so that electrons are vibrated

in a horizontal direction via the electric field

around the antenna, which leads to higher electron density

than other plasma sources due to low absorption of electrons

by electrodes (high-density plasma) - Etching is done by attracting ions from a bottom bias electrode